Measham Outfitting – 31st. January – Central Heating System, Kitchen Fitting, and Bathroom Fitting

In the past week the biggest single item of progress has been the installation of the central heating system into the narrowboat.

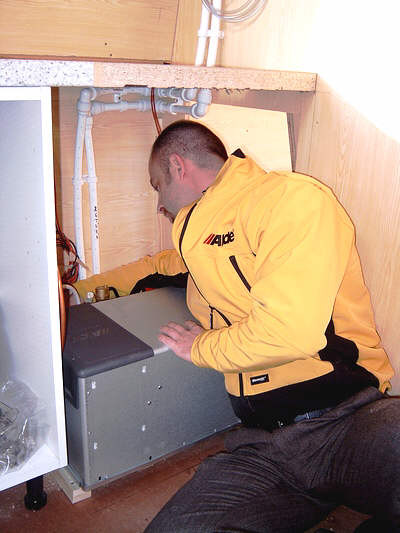

The central heating boiler chosen is the Alde Compact 3010 as used in the boat Carlton.

As you will see this is an extremely compact boiler that is capable of very efficiently producing 6.4kW. of heat.

The compact nature of any central heating boiler used on a canal boat is a very important factor.

Also, for the first time, a heat exchanger unit, recently developed by Alde, has been fitted between the engine bay mounted calorifier and the central heating system.

This will allow engine produced heat to be “exchanged” and circulated around the radiators.

Little further text will be added, the pictures doing the “talking”.

The boiler unit is mounted at the rear of the galley.

For those of you who would like further information on this heating unit, i.e. the Alde 3010 Compact Combi HF Boiler, visit their website, www.alde.co.uk

In the past week the biggest single item of progress has been the installation of the central heating system into the narrowboat.

The central heating boiler chosen is the Alde Compact 3010 as used in the boat Carlton.

As you will see this is an extremely compact boiler that is capable of very efficiently producing 6.4kW. of heat.

The compact nature of any central heating boiler used on a canal boat is a very important factor.

Also, for the first time, a heat exchanger unit, recently developed by Alde, has been fitted between the engine bay mounted calorifier and the central heating system.

This will allow engine produced heat to be “exchanged” and circulated around the radiators.

Little further text will be added, the pictures doing the “talking”.

The boiler unit is mounted at the rear of the galley.

For those of you who would like further information on this heating unit, i.e. the Alde 3010 Compact Combi HF Boiler, visit their website, www.alde.co.uk I suppose it is relatively simple to install if you know what you are doing, but it appears rather complicated to me.

I suppose it is relatively simple to install if you know what you are doing, but it appears rather complicated to me. Looking at the rear of the boiler unit from above.

Looking at the rear of the boiler unit from above. The boiler and all pipework and radiators were fitted by a local engineer, however an engineer from Alde came to check that everything had been correctly installed before testing.

The boiler and all pipework and radiators were fitted by a local engineer, however an engineer from Alde came to check that everything had been correctly installed before testing. As you can see the galley work top has already been installed, and the whole of the boiler installation will be enclosed once everything is shown to be performing correctly.

As you can see the galley work top has already been installed, and the whole of the boiler installation will be enclosed once everything is shown to be performing correctly. This is a picture of the compact heat exchanger recently developed by Alde.

This unit will “exchange” heat from the water cooling the engine so that it can be used in the central heating system, thus reducing the amount of bottled gas used.

This will mean that hirers who hire boats for extended periods will be required to change gas bottles less frequently.

(It is necessary to point out that all gas used during the hire period is paid for by Ashby Boat Company providing receipts are kept as proof of purchase.)

The pipes passing through the wall to the right are passing in to the engine bay.

This is a picture of the compact heat exchanger recently developed by Alde.

This unit will “exchange” heat from the water cooling the engine so that it can be used in the central heating system, thus reducing the amount of bottled gas used.

This will mean that hirers who hire boats for extended periods will be required to change gas bottles less frequently.

(It is necessary to point out that all gas used during the hire period is paid for by Ashby Boat Company providing receipts are kept as proof of purchase.)

The pipes passing through the wall to the right are passing in to the engine bay. The radiators throughout the boat have now been fitted, as the images to the left and below show.

The radiator capacities are carefully chosen to work with the kW output of the Alde boiler.

The radiators are mounted under the windows where possible and chosen to match the space and usage requirement of the area.

The radiators throughout the boat have now been fitted, as the images to the left and below show.

The radiator capacities are carefully chosen to work with the kW output of the Alde boiler.

The radiators are mounted under the windows where possible and chosen to match the space and usage requirement of the area. Although the bulk of the progress has been related to the boiler installation and the central heating system other work has been ongoing when there has not been a conflict of requiring the same “space” to work.

Work on the fitting out of the galley has been taking place.

To the left and below are images of Rob and Colin using a router to prepare the work top for fitting in to the galley, as already seen above.

The fitting out of the compartment containing the toilet and the wash-hand basin has also been taking place, see the images to the right and below.

This compartment will have mirrors, vanity units, storage space, etc., as further images at a later date will show.

Although the bulk of the progress has been related to the boiler installation and the central heating system other work has been ongoing when there has not been a conflict of requiring the same “space” to work.

Work on the fitting out of the galley has been taking place.

To the left and below are images of Rob and Colin using a router to prepare the work top for fitting in to the galley, as already seen above.

The fitting out of the compartment containing the toilet and the wash-hand basin has also been taking place, see the images to the right and below.

This compartment will have mirrors, vanity units, storage space, etc., as further images at a later date will show. The radiator fitted and the pipes already boxed in, hard wood edging will be fitted last to cover all “raw” edges.

The radiator fitted and the pipes already boxed in, hard wood edging will be fitted last to cover all “raw” edges. The wash-hand basin will be fitted in to the top of this unit, that will also provide storage.

The wash-hand basin will be fitted in to the top of this unit, that will also provide storage. Storage space at the rear of the boat, on the right looking to the front of the boat, you can see the open rear door.

If you look closely you can see the heat exchanger at the bottom of this unit, partly obscured by loose wiring.

Storage space at the rear of the boat, on the right looking to the front of the boat, you can see the open rear door.

If you look closely you can see the heat exchanger at the bottom of this unit, partly obscured by loose wiring. The storage unit to the rear of the boat on the left hand side.

The top compartment will be where various switches and engine monitoring controls are fixed.

The storage unit to the rear of the boat on the left hand side.

The top compartment will be where various switches and engine monitoring controls are fixed.